Fundamental Information of Hollow Fiber Membrane

Hollow Fiber Membranes and Separation Mechanisms

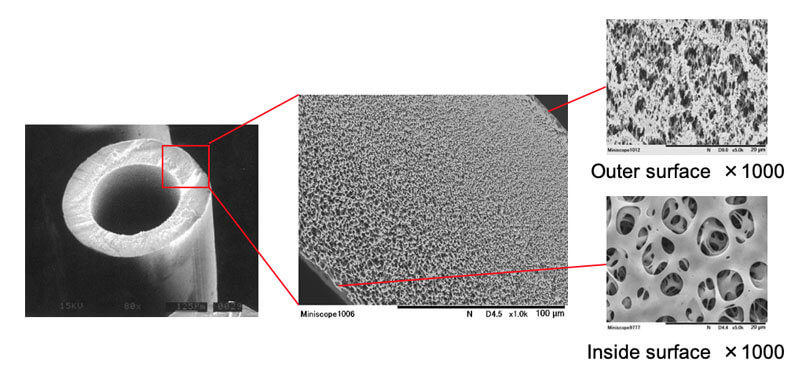

The hollow fiber membrane is a separation membrane shaped like a thin straw. Generally, it has a diameter of about 0.5~1.0 mm, and has micropores composed of a 3D mesh structures. And it has an asymmetric structure with a characteristic dense layer (skin layer) on the inside or outside surface. The size of the substance to be separated is divided into separation methods called Micro Filtration(MF), Ultra Filtration(UF), Nano Filtration(NF), and Reverse Osmosis(RO). It is also applied to gas separation membranes that utilize the difference in gas permeability coefficients between oxygen O2 and nitrogen N2 in the air. GS Yuasa Membrane provides the hollow fiber membranes, mainly in the MF area.

GS Yuasa Membrane Hollow Fiber Membrane Pore Diameter 0.45 μm

Phase separation membrane forming method

The hollow fiber membranes are produced using two types of wet processes. GS Yuasa Membrane specializes in the NIPS method and offers a wide variety of thread and pore diameters.

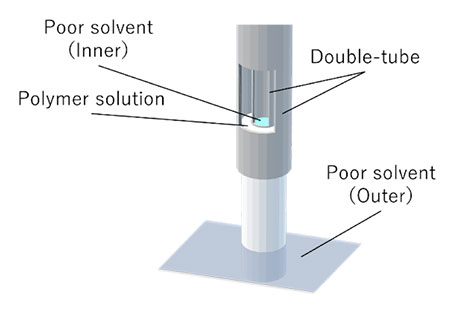

Nonsolvent Induced Phase Separation:NIPS

This phase separation method is mainly used to form the hollow fiber membranes in the MF and UF areas. The membrane is formed using a needle with a double-tube structure. A multi-component polymer solution consisting of polymer, solvent, and additives is pumped into the outer tube, while poor solvent is pumped into the inner tube. Immersion in the external solution forms the membrane structure. The inner and outer surfaces of the skin layer are controlled by changing the composition and type of the inner solution and outer poor solvent. This skin layer has the characteristic of inhibiting fouling.

Thermally Induced Phase Separation:TIPS

This phase separation method is used to form a wide variety of hollow fiber membranes from MF to gas separation. A simple high-boiling solvent polymer solution consisting of polymers and oils is dissolved at high temperatures, and forms a membrane structure by crystallization or solidification through cooling.

Filtration method

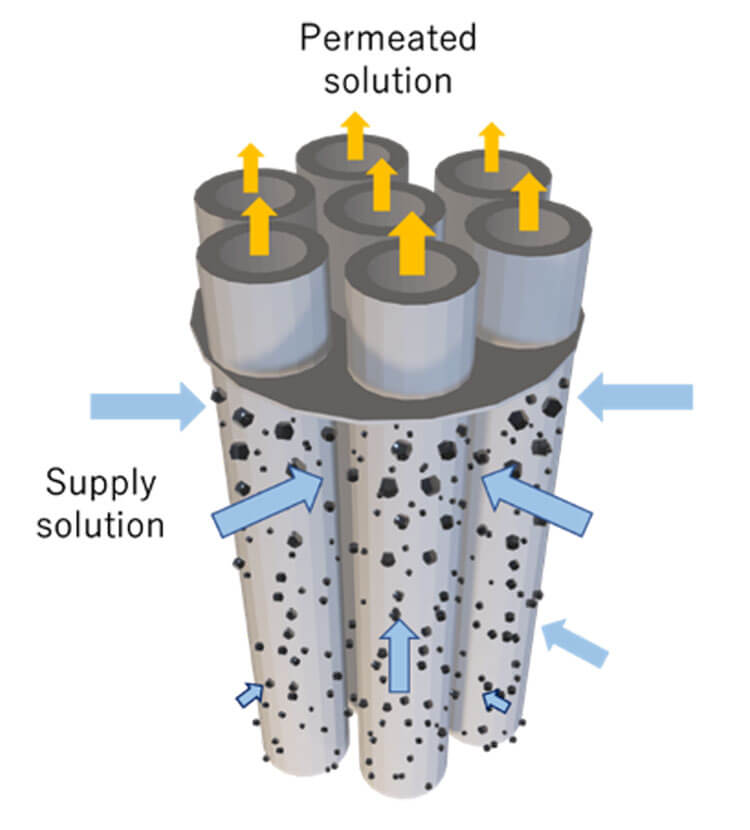

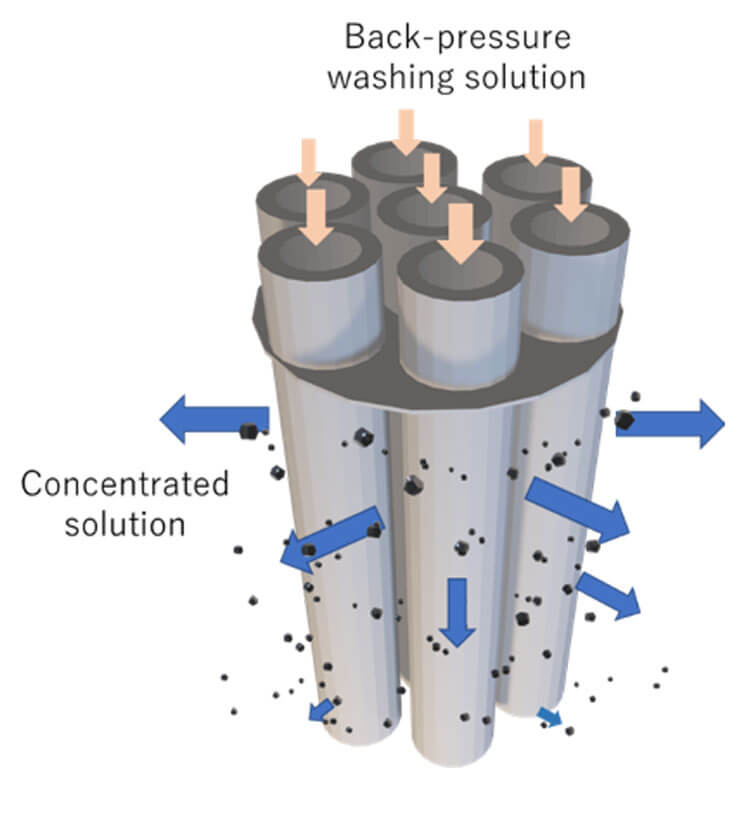

Dead-end filtration method

The dead-end filtration method applies pressure from the outside to the inside of the hollow fiber membrane. The entire volume is filtered without losing anything. The formation of a sedimentary layer (cake layer) of the substance can remove particles finer than the microporous size of the membrane. The permeate volume is maintained by periodically removing the cake layer through back-pressure washing using permeate or chemical solutions.

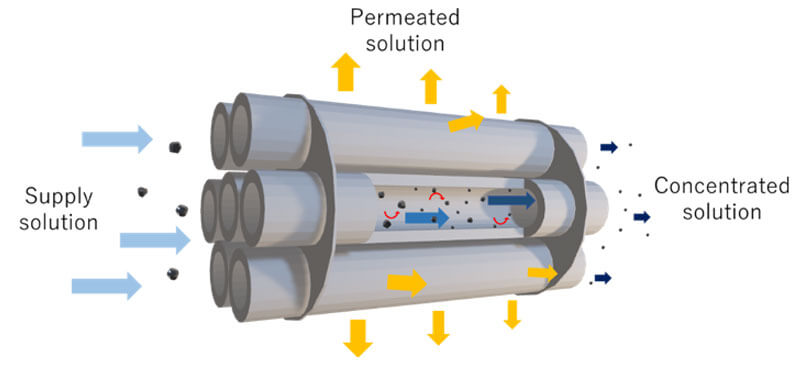

Cross-flow filtration method

The cross flow method feeds the supply solution into the inside of the hollow fiber membrane and allows it to permeate from the inside to the outside. The flow of the supply solution allows filtration and concentration while inhibiting sediments on the membrane surface (inhibiting fouling).

Type of Hollow Fiber Membrane Element

Hollow fiber membrane elements are completely separated from the supply and permeate sides by sealing the gap between the hollow fiber membrane and the element case with potting. The potting agent is molded with thermosetting resins such as urethane or epoxy resins. Elements of hollow fiber membranes are manufactured using each company's proprietary technology. Here are some examples from GS Yuasa Membrane.

Dead-end element

The dead-end element features a U-shaped one-sided potting. Its superior strength and chemical resistance allows for chemical back-pressure washing to recover permeability.

Cross-flow element

The cross-flow element features I-shaped dual-sided potting.The precisely controlled skin layer and pore size provide stable permeate and concentrate while inhibiting fouling.

We will propose the variety of membranes and the best filtration systems that makes use of our abundant know-how according to your solution.

If you have any questions, please feel free to contact us.