Fundamental Information of Filter Membrane

Separation target and Mechanism

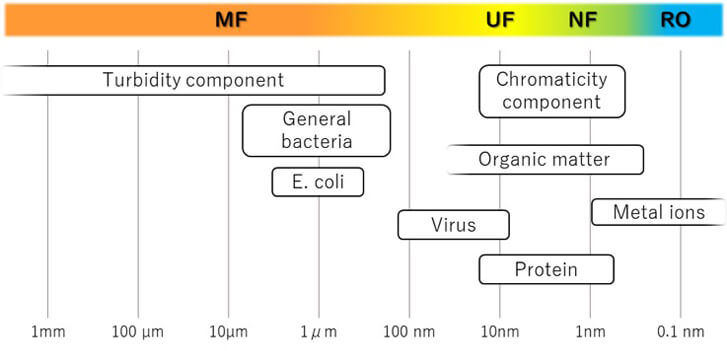

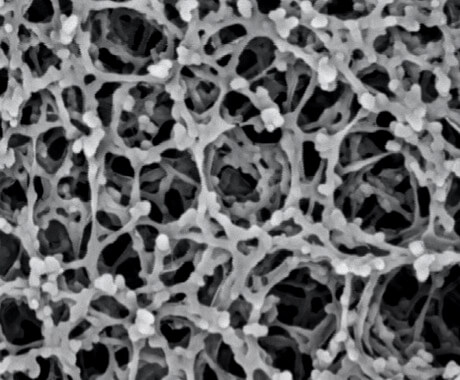

The filtration membrane can selectively separate substances such as macromolecules and particles in the liquid. Generally, the size of the substance to be separated is divided into separation methods called Micro Filtration(MF), Ultra Filtration(UF), Nano Filtration(NF), and Reverse Osmosis(RO). GS Yuasa Membrane offers various types of membranes, mainly in the MF area. The filtration membrane was observed many micropores of 3D network structure with the electron microscope, and it is possible to "sieve the substance" like a colander.

ex.) Membrane Filter MF-90B ×5000

Phase separation membrane forming method

The membrane structure of the filtration membrane could be controlled by the membrane-formation method. It is necessary to select a membrane structure with a higher filtration effect according to the properties of the liquid to be filtered and the use applications. GS Yuasa Membrane has established a unique membrane-forming technology with high quality. In addition, we will construct an optimal filtration system by various membrane technologies such as flat membrane membrane-forming technology, hollow fiber membrane-spinning technology, and radiation graft-polymerization technology.

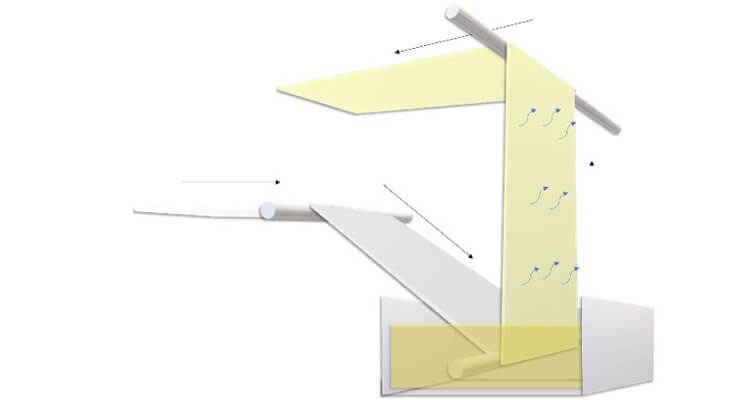

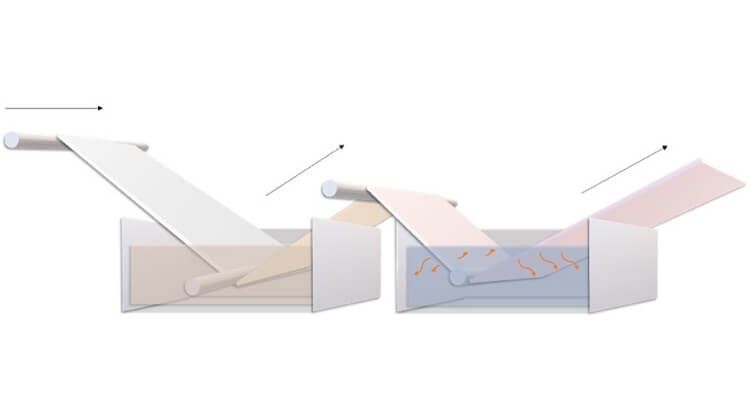

Dry phase separation

The membrane structure of uniform micropores was formed by applying a solution containing a membrane material to a non-woven fabric substrate and taking in moisture in the air while evaporating the solvent.

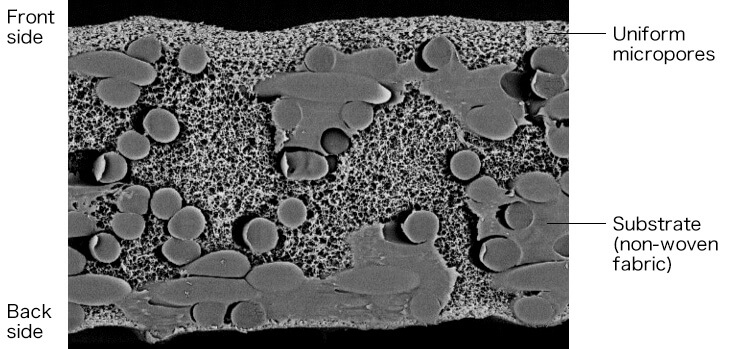

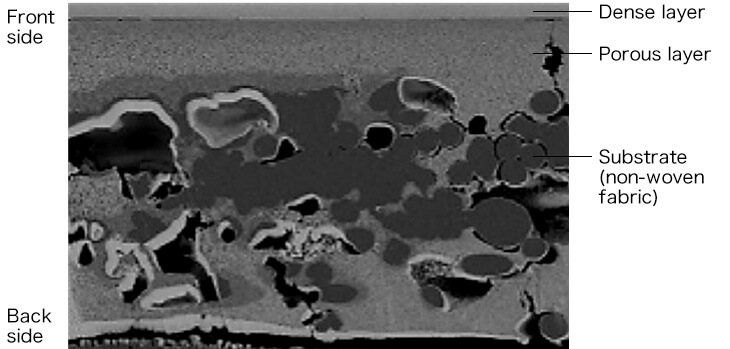

Dry phase separation membrane Cross section

Wet phase separation

The characteristic membrane structure of dense layer on the surface was formed by applying a solution containing a membrane material to a non-woven fabric substrate and immersing it in a poor solvent such as water.

Wet phase separation membrane Cross section

Filtration method

There are roughly two types of filtration methods, and it is necessary to determine them according to the properties and concentration of the solution to be filtered, membrane separation performance, module form, etc.

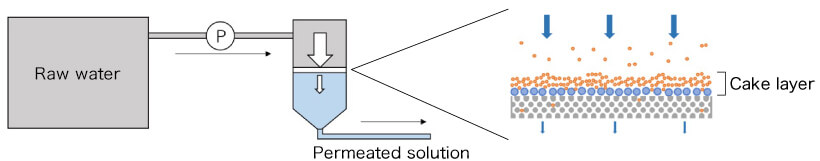

Dead-end filtration method

The dead-end filtration was filtered without dropping the substances to be filtered pressurizing the supply side or depressurizing the permeation side. It was possible to remove particles finer than the micropore size of the membrane by forming a sedimentary layer (cake layer) of the substances to be filtered,

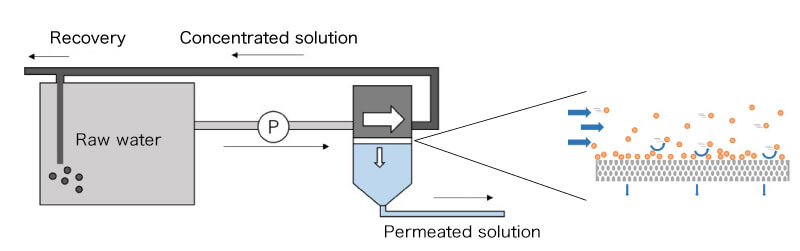

Cross-flow filtration method

The cross-flow filtration was filtered and concentrated while inhibiting the sediment on the membrane surface by the flow of the supply solution. It was possible to recover the concentrated solution in-line.

Type of membrane elements and modules

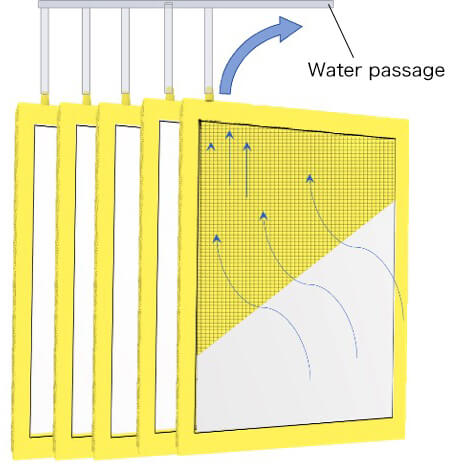

Flat type elements

The both sides flat membrane element was processed welding or adhering the resin frame and the filtration membrane.

The supply solution was filtered from the outside to the inside of the element by absorption from the water passage.

Whereas typical element inserts a spacer between a membrane and a support to ensure a passage for the permeate solution, GS Yuasa Membrane has the unique elements that possess the slit in the support. The required amount of processing could be achieved modularizing dozens to hundreds of elements and processing them in parallel.

The schematic diagram

Immersion type flat membrane module

The immersion type flat membrane module performed filtration by immersed in the solution and absorbed it with a pump. We will introduce the Membrane Bio Reactor (MBR) as the main introduction example. In addition to MBR, it has a wide range of uses such as metal drainage and valuable materials recovery.

The Bio Reactor method is the decomposition and purification of organic matter such as kitchen wastewater, sewage, and factory wastewater by the microorganisms effect. Accordingly, BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) is dropped down to below the effluent discharge standard.

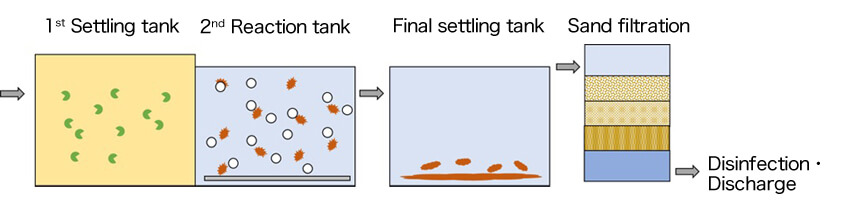

Traditional Bio Reactor method

The first step of the traditional Bio Reactor method was performed decomposition and aggregation precipitation with anaerobic microorganisms in the 1st settling tank, and decomposition by aerobic microorganisms in the 2nd reaction tank. Next step was performed natural sedimentation in the final settling tank, and sand filtration the overflow solution. Moreover, after disinfection of Escherichia coli, it was possible to discharge the processing solution into river.

Traditional Bio Reactor method

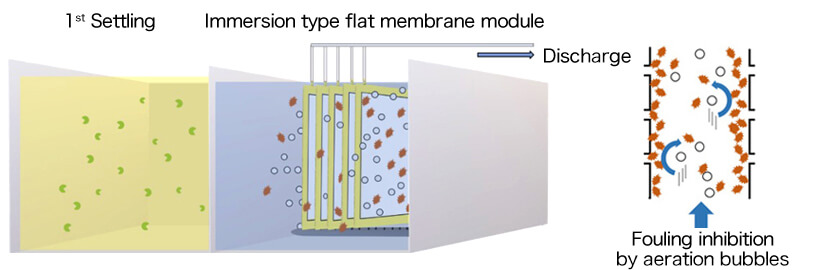

Membrane Bio Reactor(MBR) System with the immersion type flat membrane module

The first step of the MBR system was also performed decomposition and aggregation precipitation with anaerobic microorganisms in the 1st settling tank. In the 2nd reaction tank, the processing solution decomposed by high-concentration aerobic microorganisms was directly filtered with the flat membrane module. In addition, aeration bubbles were thinly removed fouling substances adhering to the membrane surface. Therefore, this is the system that combined the advantages of the dead-end method that could filter fine bacteria without missing them and the cross-flow method that could inhibit fouling. The treated solution that was filtered in this way could be discharged without a disinfection process , because they were removed Escherichia coli at the same time in one step. In addition, since the number of large tanks could be reduced, many site areas could be saved.

Membrane Bio Reactor(MBR) System

Advantages of MBR in wastewater treatment

- Compacting and space-Saving drainage facility.

- Efficient decomposition because of One-step without the final settling tank.

- Activation of aerobic microorganisms and Fouling Inhibition by Aeration.

- It could be discharged without a disinfection process.

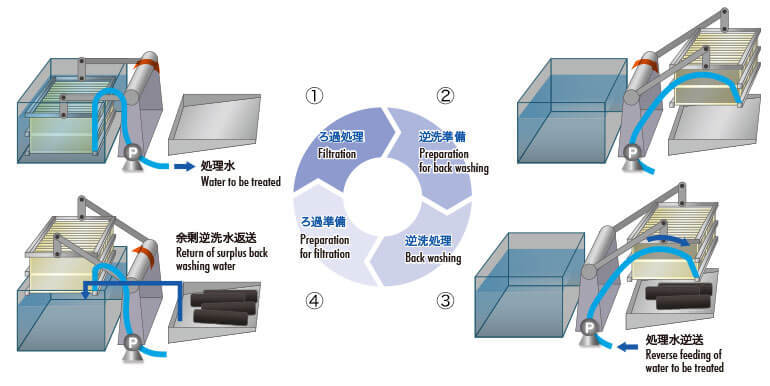

Backwash type flat membrane module

In the backwash type flat membrane module, the cake layers were peeled off and recovered in a flash with the minimum amount of filtered water by back pressure washing, after formed by immersion in a raw solution and absorption filtration as in the case of the immersion type. This method has been using in a wide range of fields for valuable resource recovery without a coagulant, sludge dewatering, and filter press pretreatment. We have a lot of experience and achievements of them.

The backwash device is a filtration and concentration and recovery system that "makes use of the feature that a cake layer is formed".

- The cake layer was formed on the surface of the flat membrane by the filtration process.

- Move the flat membrane module.

- The cake layer was lifted by the backwash water that seeps out from the micropores, and shaken off by vibration.

- Immerse it in the solution again and filter it.

The backwash type flat membrane module is continued to automatically perform the above cycles ① to ④. The extremely strong strength of our flat membrane element is one of the reasons why back pressure washing made it possible. Concentration, dehydration, and recovery could be performed more efficiently and lower energy and cost than other methods.

We will propose the variety of membranes and the best filtration systems that makes use of our abundant know-how according to your solution.

If you have any questions, please feel free to contact us.