Electrolytic Diaphragm For Plating

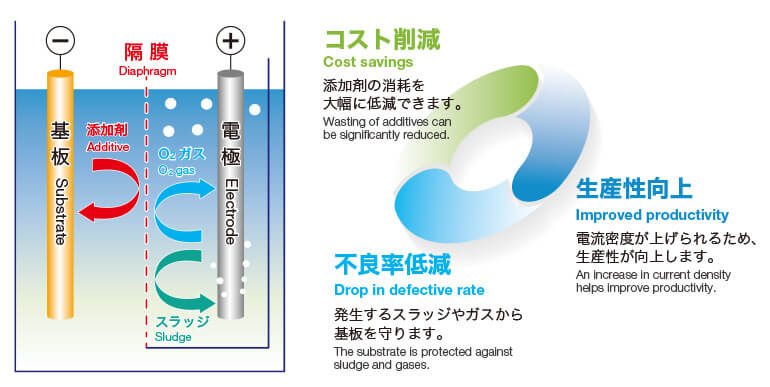

The electrolytic diaphragm controls the consumption of additives and enhances plating performance.

Newly released "Y-9207TA".

The effective width was 1.5 times compared with a conventional product.

This products contributes to the above goals among the SDGs.

Features

- Being microporous, the neutral membrane involves low electric resistance and smaller movements of liquid.

- Highly resistant to chemicals.

- It can be handled easily because it can be kept in dry conditions before use.

- It can be processed in many different forms such as slit, bag and frame welding.

- Less expensive than ion exchange membranes.

Applications

- Diaphragm for copper plating (especially effective in printed circuit boards necessitating fine controls, such as via filling and through hole)

- Diaphragm for nickel plating

- All applications of electric plating

Specifications

| Model | Material | Thickness*1 (mm) |

Electricity resistance*2 (Ω・cm2) |

Membrane polarity |

Water permeability (sec/ml/13.8cm2 at 50.7kPa、25℃) |

Storage | Processing Width*3 (mm) |

|

|---|---|---|---|---|---|---|---|---|

| Membrane | Base | |||||||

| Y-9205TA | Polyvinylidene fluoride Titanium oxide Sucrose fatty acid ester |

Polyethylene Terephthalate |

0.22 ±0.03 |

≦0.90 | Neutral | ≧10 | Can be stored in dry conditions | 500 |

| Y-9207TA | 0.17 ±0.04 |

750 | ||||||

1micrometer

2NaCl aqueous solution 20wt%

3We wii cut it desired length

The information shown above are representative values and are not guaranteed.

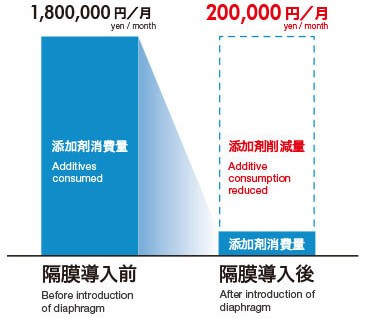

Effects of the diaphragm

Comparison of cost for additive (examples)

| No diaphragm | With diaphragm | Cost savings | 1,800,000yen/month | 200,000yen/month | 1,600,000yen/month |

|---|

for a plating area of 10,000m2/month