Immersion Membrane Modules

This products contributes to the above goals among the SDGs.

This products contributes to the above goals among the SDGs.

Immersion Membrane Modules is a tank-immersion-type module for a large-capacity membrane filtration using the precision filtration membrane (Membrane Filter) that was originally developed by GS Yuasa Membrane.

Immersion Membrane Modules involves immersing a precision filtration membrane in water in the tank, to separate solids from raw water. This eliminates bacteria and fine particles and helps obtain treated water of consistent quality.

Features

- Space saving

- ・No sedimentation basin or filtration machine is required. Overall, it occupies a smaller space for installation.

- ・It allows for high-load operation.

- ・High efficiency in membrane volume

- Energy saving

- ・The original element structure allows for membrane separation at low pressure.

- ・Power cost can be saved with suction filtration or gravity filtration.

- ・The reinforcement frame of the element enhances durability and allows for long operation.

- Easy maintenance

- ・Precision filtration ensures consistency in the quality of treated water.

- ・The membrane surface is cleaned by aeration, which helps maintain the filtration's performance for a long period.

- ・Each element is disposable and replaceable. It is easy to handle.

- High-concentration operation

- ・The membrane module allows for operation in highly concentrated liquid more than the hollow fiber membrane does.

- ・It can also be used to condense sludge.

Applications

- Treatment of wastewater from semiconductor plants

- Treatment of wastewater from general plants

- Service water purification process

Specifications

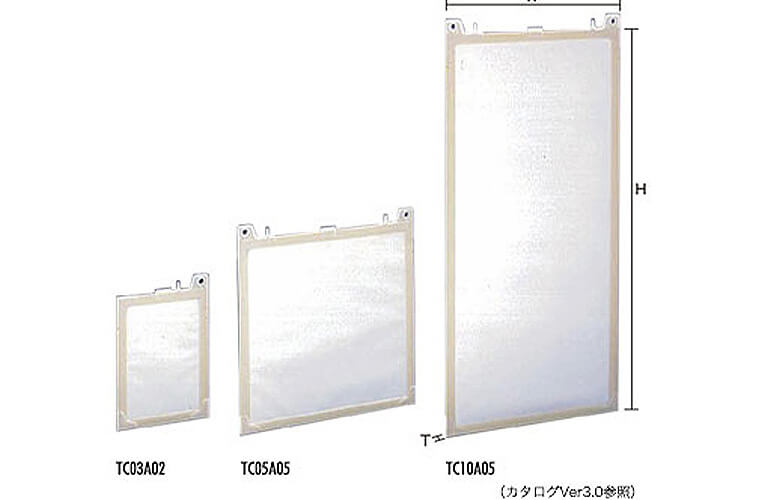

Immersion Membrane Element

| Model | Material | Effective

membrane area m2 |

External dimension mm |

Nominal pore size μm |

Standard filtration flux m/day |

Operating

temperature range °C |

Operating

pressure range kPa |

Applicable pH range pH |

|

|---|---|---|---|---|---|---|---|---|---|

| Membrane | Base | ||||||||

| TC 10A05H |

Membrane Filters: Chlorinated polyvinyl chloride、 Sucrose fatty acid ester Spacer: Polypropylene or Polyester Plate: PVC、ABS、Polypropylene |

Polyethylene terephthalate |

0.8 | W490× H1000× T6*1 |

0.25 | 0.2〜1.0*2 | 0〜40*3 | -49〜0 | 3〜10 |

| TC 10A05S | W490× H1000× T7.5*1 |

||||||||

| TC 05A05S | 0.4 | W490× H490× T7.5*1 |

|||||||

| TC 03A02 | 0.1 | W240× H340× T7.5*1 |

|||||||

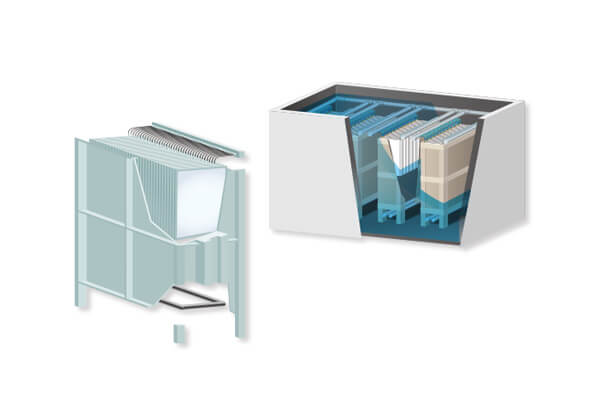

Immersion Membrane Unit

| Model | Membrane Unit | External

dimension D×W×H(mm) |

|

|---|---|---|---|

| Quantity | Membrane area(m2) | ||

| TC10A05-50 | 50 | 40 | 792×600×1,520 |

| TC10A05-75 | 75 | 60 | 1,142×600×2,020 |

| TC10A05-100 | 100 | 80 | 1,494×600×2,020 |

| TC10A05-125 | 125 | 100 | 1,846×600×2,020 |

| TC10A05-150 | 150 | 120 | 2,205×600×2,020 |

| TC10A05-200 | 200 | 160 | 2,925×620×2,020 |

Element:TC10A05

1For improvements, the external dimension may be changed without prior notice.

2The filtration flux depend on the condition of its use.

3Do not freeze.

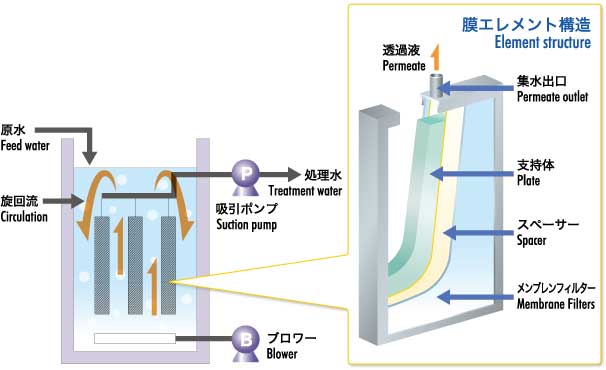

Immersion and membrane separation system

Immersion Membrane Modules involves immersing a membrane element in water in the tank and filtering it by suction and gravity. On the membrane surface, suspension particles form a dynamic filter layer.

Furthermore, the aeration cleaning from the bottom of the tank prevents membrane blockage and thus allows for long operation in high-concentration wastewater.

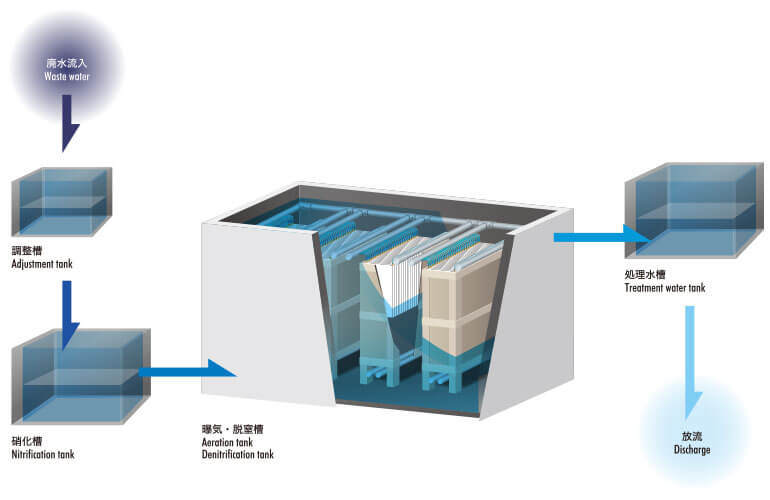

Installation of activated sludge treating sysytem

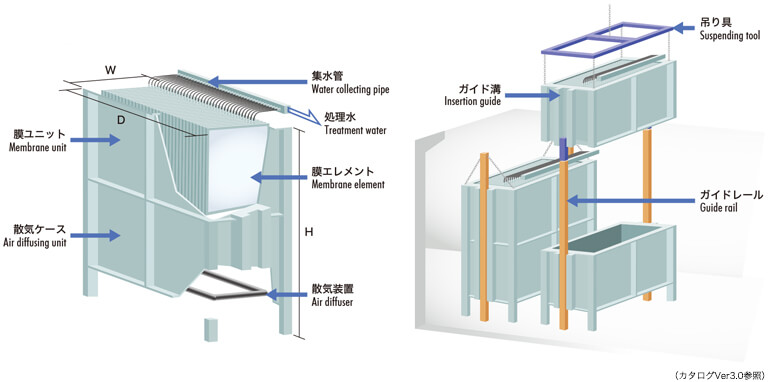

Membrane module structure

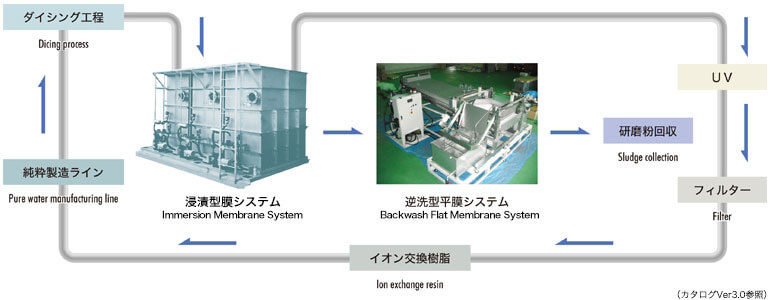

Flow sheet of wastewater treatment of dicing process

Membrane element

Appearance and characteristics

- With the original element structure, it can be operated at low pressure.

- Each element is disposable and replaceable. It is easy to handle.

- The reinforcement frame of the element enhances durability and allows for long operation.