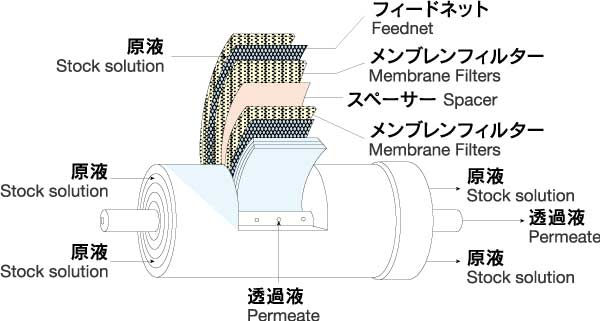

Spiral Membrane Modules

Spiral Membrane Modules feature membrane elements prepared by forming microporous membranes develop in spiral form enclosed in housings.

Filtration systems utilizing these easy-to-handle modules are reputed to have outstanding reliability based on the operation expertise accumulated over a long period of time, and have an extensive delivery track record.

This products contributes to the above goals among the SDGs.

Structure of Spiral Membrane Modules

Features

- Excellent chemical resistance for applicability in a wide pH range from 1 to 12.

- Cumbersome wet storage is not required because they are dry membranes.

- Higher paint recovery rate, lower pure water consumption and lower effluent load in combination with reverse osmosis (RO) membranes.

- Four different types of modules designed for different treatment capacities to cover a wide range of water volumes.

Applications

- Electropainting Process

Recovery of cation, anion and clear electro-deposition paints

Specifications

Membrane Module + Housing

| Model | Exterior dimesions mm |

Housing materials | Effective firtration area m2 |

Withstanding pressure MPa |

Withstanding heat ℃ |

Paint circulation rate L/min |

Designed firtration volume L/min |

|---|---|---|---|---|---|---|---|

| YSP-75M | φ102×1180 | PVC | 3 | 0.4 | 35 | 50〜70 | 0.3〜0.7 |

| YSP-100M | φ130×1185 | PVC | 7 | 0.4 | 35 | 70〜90 | 1.0〜2.0 |

| UFC-150N | φ175×1330 | FRP/PVC | 19 | 0.4 | 40 | 140〜160 | 4.0〜8.0 |

Membrane Module

| Model | Exterior dimesions mm |

Housing materials | Effective firtration area m2 |

Withstanding pressure MPa |

Withstanding heat ℃ |

Paint circulation rate L/min |

Designed firtration volume L/min |

|---|---|---|---|---|---|---|---|

| UFC-130N | φ130×1034 | SUS* | 10.5 | 0.4 | 40 | 120〜150 | 1.5〜4.0 |

A special housing is required separately.